Blockchain technology has been stirring imaginations and encouraging innovation since before even going live, and the possibilities seem to be showing no signs of slowing down anytime soon.

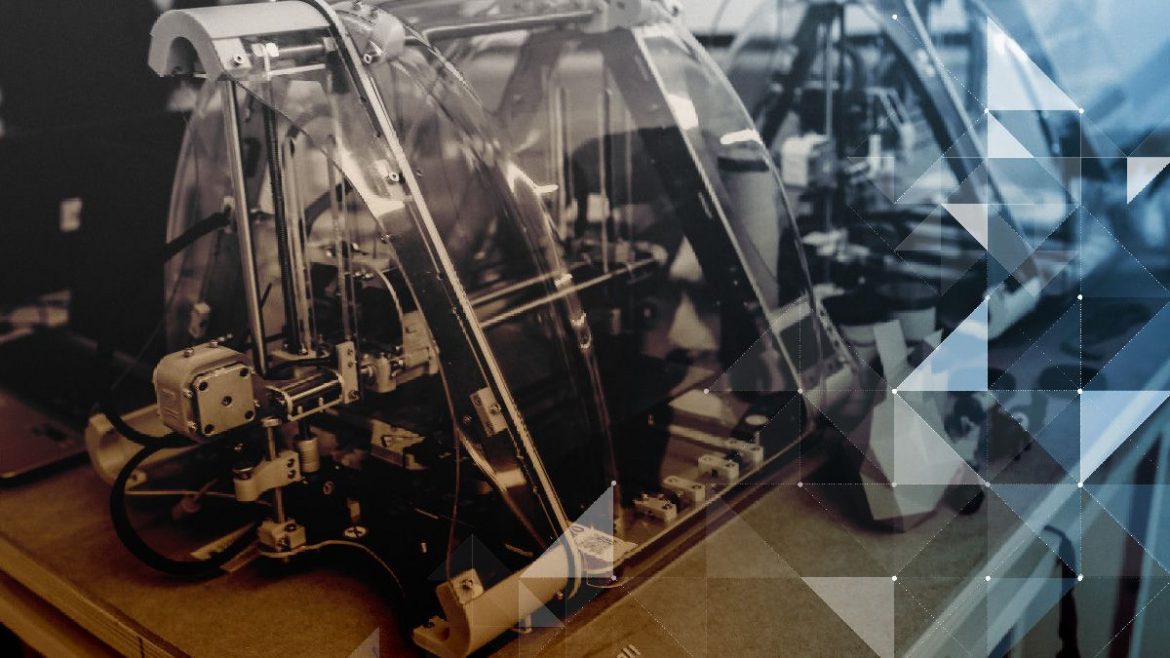

The same can be said about 3D printing. Additive manufacturing, or 3D printing, is a process by which three dimensional solid objects are created from a digital file. Creative designers have utilized this technology to create everything from small, intricate machinery parts to functioning firearms and everything in-between.

3D printing is a rather intense technological process. The procedure, which naturally involves the manufacturing data being transmitted which of course means that it’s necessary to distribute and transmit that data safely. Blockchain networks are of course ideal for the trustless exchange of data when it comes to capital, so it’s not a far stretch at all to look at ways they could be utilized for distributed peer-to-peer 3D modeling and printing marketplaces.

Recent research from Deloitte pointed out a need for a “digital thread” within the 3D printing industry. The thread would function as a single strand of data that links design concept to the finished part. Additionally, in order for the 3D printing industry to be able to scale as the industry dictates, they have to have the ability to track and utilize an immutable ledger for logging of complex data-driven events.

The near real-time settlement and exchange functionality of blockchain allows for instantaneous design changes and along with the distributed nature of blockchain, many believe that the 3D printing industry could benefit quite nicely from blockchain integration.

The spin-off of the Italian University “Politecnico di Torino,” Politronica Srl, wants to bring a whole new level to small-to-medium scale just-in-time digital manufacturing via the 3D-TOKENS project. While they currently maintain a network of 100 3D printers, with the 3D-TOKENS project they are projecting an increase of up to 3,000 by the end of the year, with 1,000 network members and an impressive production capacity of up to 300 tons of processed bioplastics.

Politronica Srl has also managed to broker a deal through its current network with such industry giants as the design shop chain Flying-Tiger Copenhagen that has 600 shops globally. Through this collaboration, they’ll roll out an innovative desktop 3D printing learning device and lamp called Q3D during the coming months.

Genesis of Things is also at the forefront as an innovator in the combined industries, building a “distributed global factory that delivers products when and where needed, while protecting all stakeholder’s rights.” This platform will allow users to find and contract the best 3D printer for their production needs, securely transfer production files directly into a 3D printer, with zero human access, set up smart contracts to regulate, track and automate access, use, logistics, rights and payments, as well as tag products with a traceable, non-editable digital product memory.

Blockchain technology and 3D printing appear to be set for a long future together, and the next 12 months should be quite telling.

How Blockchain Can Revolutionize 3D Printing

previous post